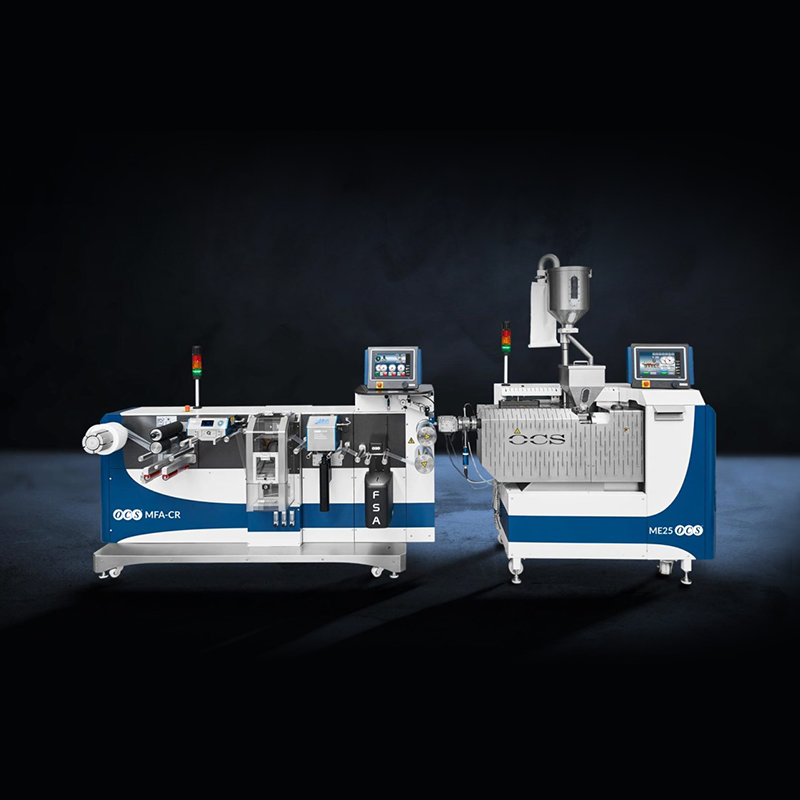

Cast Film Line

The OCS Cast Film Line is used to perform optical and physical property measurements of polymers in the production of high-quality cast (flat) films (extrusion, cooling, stripping and winding). All settings and parameters, e.g. extruder speed, temperature, film tension, winding force, winder diameter, are stored by a touch panel control system which guarantees that the film quality can be reproduced at any time. This is an important parameter for optical and physical on-/offline measurements, for example in detecting gels, contaminations, degradations and other impurities as well as haze, gloss, density and additive measurement.

Possible testable polymers include, for example, PP, PET, PC, HDPE and LDPE.

Testable Raw Materials

- Pellets, powders and flakes

Module I + II (included)

- Measuring Extruder (ME20/ME25/ME30/ME40/ME45) with fix lip die 50–150 mm or flex lip die 150–350 mm

- Modular Film Analyzer with two chill rolls (MFA-CR)

- Film Surface Analyzer (FSA100V2/FSA200V2)

Features

- Measuring Extruder (ME) comes with flexible height adjustment (infusion position)

- Maintenance and cleaning positions of the Measuring Extruder (ME) can be approached by means of an electric motor

- Modular architecture of the Modular Film Analyzer (MFA) to facilitate customization of additional measuring devices

- Operation via touch panel with data trend as well as optical and acoustic alarm functions

- All system parameters are monitored and saved in the touch panel control system

- Several options are available for data communication