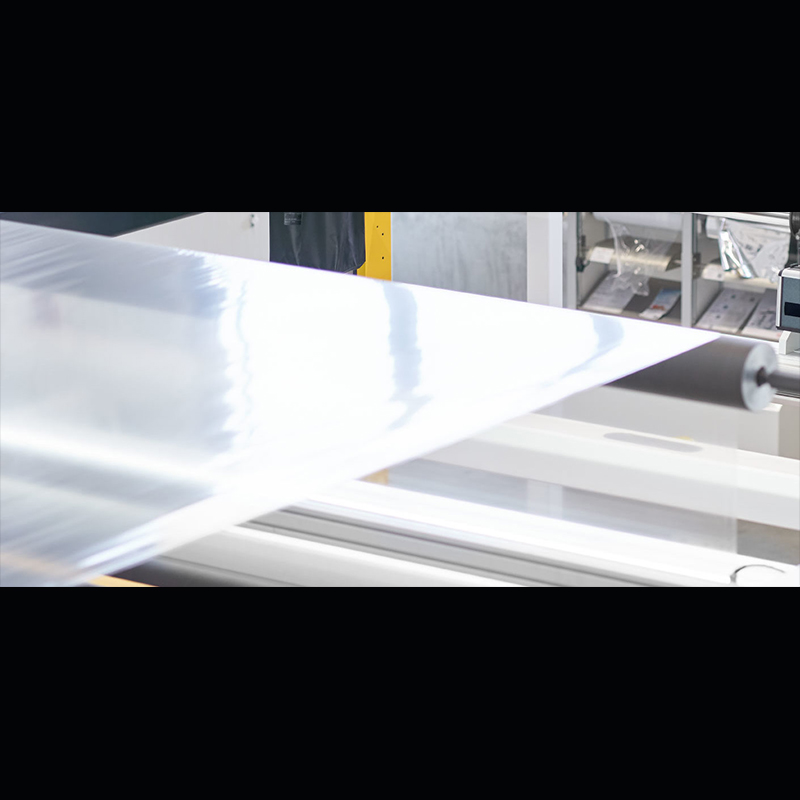

Web Inspection System (FSP600)

With the OCS Web Inspection System FSP600, all types of irregularities in films, laminates and non-wovens can be detected in real time using high-speed cameras. They defect often reduce the quality of the film and the end product. These include gels, burners (black specks), fisheyes, holes, wrinkles, scratches, coating defects, water droplets, oil stains, insects, bubbles, nozzle marks and craters, etc.

Additional features of the FSP600 system are the data transfer of real-time results to the production and process control as well as product improvement by sorting/labelling contaminated web sections.

Testable Products

- Blown films, cast (flat) film and plate lines (PP, PET, PE, ABS, PC, PMMA, etc.)

- Coating films (aluminum, painted, etc.)

- Biaxial stretch films

- Surface protection films

- Medical and pharmaceutical films

- Optical films

- Food and barrier films

- Hygiene and nappy films, non-woven and laminates

- Technical films, etc.

Features

- Can be combined with transmission and reflection LEDs as well as dark and bright field applications

- Works with up to 6 channels simultaneously through MCE (Multi Channel Evaluation)

- LEDs can be controlled and triggered in sequence

- LEDs with passive cooling available in red, white, blue, UV or IR wavelengths, meeting the IP54 standard (water drop protection)

- Universal OPC-UA interface (BDE connection, connection of external sensors, e.g. metal detector, reading of machine parameters and CSV output)

- Simple Windows-based software with data management options and cut optimization

- Teach-in of error references (teach-in function)

- Standardized classification of the film roll (calculation of marks)